of themWelcome to the comprehensive guide to PLC programming! Whether you are a beginner looking to learn the basics or an experienced professional seeking to enhance your automation skills, this article is designed for you. We will cover everything you need to know about PLCs, from the fundamental concepts to advanced techniques. You will gain a thorough understanding of their role in manufacturing, different brands, input and output devices, and programming languages. Written by experts in the field and including practical examples and tips, this guide is accessible through the solisplc.com website. Let’s dive in and explore the world of PLCs together.

What is a PLC?

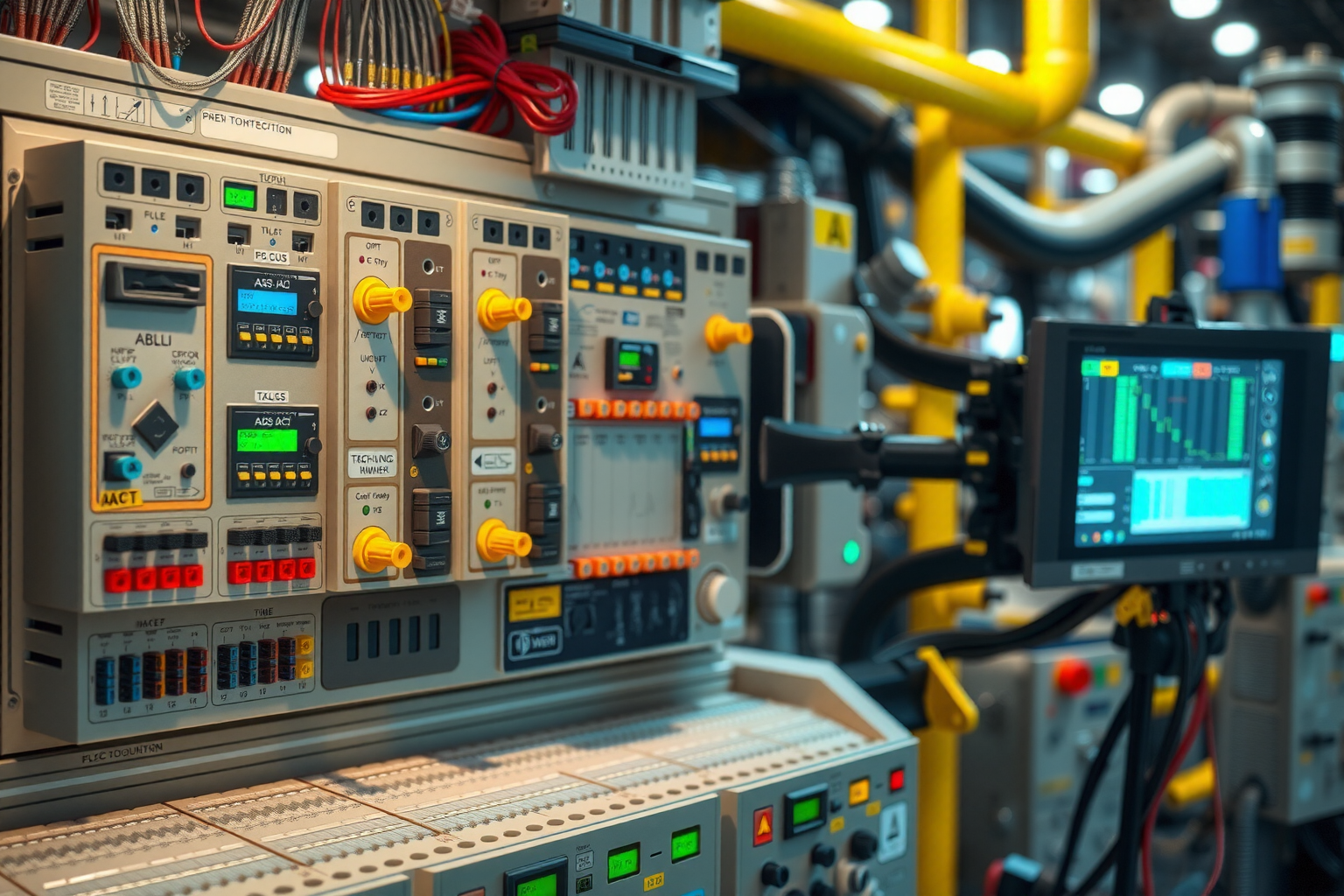

When delving into the world of industrial automation, the term PLC is one that frequently comes up. A Programmable Logic Controller (PLC) is a type of computer commonly used in manufacturing. Its ruggedness and its ability to withstand harsh conditions, such as electromagnetic interference and extreme temperatures, make it well-suited for the industrial environment. Unlike traditional computers, a PLC is specifically designed to control a variety of equipment and industrial processes. It plays a crucial role in the automation of factory assembly lines, robotic devices, aircraft and other machinery, where it is used to perform tasks and control the operation of the machines involved.

Industrial processes and machinery are often complex, and the need for precise control is paramount. This is where PLCs come in. With a robust programming capability, they are designed to carry out control and monitoring tasks by executing user-written programs. These programs, which are often customized for specific industrial applications, are implemented in the form of control algorithms. This unique approach to control and automation is what sets PLCs apart from traditional computer systems. Over the years, PLCs have evolved to become more advanced, with an increasing range of communication and connectivity options, making them indispensable in modern industrial applications.

PLC programming is a specialized field that involves the development and implementation of control programs for PLCs. In other words, it is the process of creating the specific instructions and logical decisions that a PLC will use to control and monitor industrial processes. The programming of a PLC can be carried out using various programming languages, with ladder logic, structured text, and function blocks being some of the most common. Each of these languages has its own strengths and is suited to different types of applications. As such, PLC programming is a skill that requires a deep understanding of control systems and a proficiency in the relevant programming languages.

For both beginners and experienced professionals, mastering the art of PLC programming can significantly enhance automation skills. As the demand for industrial automation continues to grow, individuals with a solid understanding of PLCs, their programming, and their role in industrial processes are highly sought after. PLC programming is not just about writing control programs; it also involves the understanding of the various components of a PLC, such as the central processing unit (CPU), input/output (I/O) modules, and communication interfaces. Additionally, a comprehensive grasp of the different types of data, as well as the implementation of best practices in PLC programming and control system design, is essential for success in this field.

Why You Should Use One?

The use of PLCs in industrial automation offers a multitude of benefits. One of the primary advantages is their high level of reliability. Unlike traditional computer systems, PLCs are designed to operate in the demanding and harsh environments typical of industrial settings. This robustness, combined with a low incidence of maintenance, makes PLCs the go-to choice for the continuous and critical control of industrial processes. In addition to their reliability, PLCs are also known for their real-time control capabilities. With the ability to respond to input changes within very short time frames, PLCs ensure that industrial processes are tightly controlled and maintained within specific parameters, further enhancing the overall efficiency and safety of the operations.

Furthermore, the flexibility and scalability of PLCs make them indispensable in a range of industrial applications. They can be easily reconfigured and expanded to accommodate changing production requirements, making them an adaptable solution for the dynamic nature of many manufacturing processes. The integration of PLCs with other industrial devices and control systems is also seamless, allowing for the central control of a diverse array of machinery and equipment. Moreover, the ability of PLCs to execute complex control algorithms with a high degree of precision and versatility, coupled with their ease of programming and maintenance, solidifies their position as the preferred choice for the automation and control of industrial processes.

With the continuous advancement of technology, the capabilities of PLCs are constantly evolving, leading to new levels of performance and functionality. This includes the integration of advanced communication protocols, support for a wider range of input and output devices, and increased processing power. As a result, PLCs are becoming an increasingly integral part of industrial automation, contributing to the overall efficiency, productivity, and safety of manufacturing and production environments. For professionals and organizations involved in industrial automation, the proficiency in working with PLCs, their programming, and the design and implementation of control systems is a valuable asset in meeting the ever-growing demands of the industry.

How Do They Work?

The operation of a PLC is based on the continuous input and monitoring of data to make real-time control decisions. PLCs achieve this through the execution of user-defined control programs, which consist of a network of interconnected instructions and logical operations. These programs, which are typically created using ladder logic, structured text, or function block diagrams, are stored in the non-volatile memory of the PLC, ensuring that the control functions are maintained even in the event of a power interruption.

Upon receiving input data from connected devices and sensors, the PLC processes this information using the logical conditions defined in the control program. This, in turn, leads to the generation of output signals that are used to control the connected output devices and actuators. The PLC continuously performs this scan cycle, which involves the reading of input devices, the execution of the control program, and the updating of the output devices. This rapid and constant cycle of input evaluation and output control allows PLCs to effectively and reliably manage the diverse and dynamic requirements of industrial processes and machinery, making them an indispensable component of modern automation systems.

In addition to their core functionality, PLCs also offer advanced features such as data logging, communication with external devices, and the implementation of safety and redundancy protocols. These features further enhance the overall performance and reliability of industrial control systems, demonstrating the pivotal role that PLCs play in the seamless and secure operation of complex manufacturing and industrial processes.

Fundamental Workings Between a PC

While PLCs and personal computers (PCs) are both form factors of computer technology, they are designed and optimized for different purposes. Unlike PCs, which are intended for a broad range of general-purpose computing tasks, PLCs are specialized for the control and automation of industrial processes. The fundamental architecture of a PLC is tailored to meet the unique operational requirements of industrial control applications, with a focus on real-time performance, robust connectivity, and the ability to withstand demanding environmental conditions.

One of the notable differences between a PLC and a PC is the way in which they handle input and output operations. In the context of industrial control, the inputs to a PLC are often derived from a diverse range of industrial devices, such as sensors, switches, and encoders. The PLC processes these inputs to make control decisions, which are then translated into outputs to operate various actuators, motors, and other connected devices. This distinct and deterministic method of I/O processing is a defining characteristic of PLCs, setting them apart from the generalized I/O operations of a PC.

Furthermore, the operating software and programming environment of a PLC are specifically tailored to support the development and execution of control programs, often utilizing specialized software tools and interfaces. This differs from the mainstream operating systems and software platforms commonly associated with PCs. As a result, the programming and configuration of a PLC typically involve a unique set of considerations and methodologies, necessitating a specialized understanding of the principles and practices of industrial control and automation.

Working With Number Systems

Another fundamental aspect of PLC programming and control system design is the understanding and manipulation of different number systems. In the realm of industrial automation, PLCs frequently handle and process data in various number systems, including binary, octal, decimal, and hexadecimal systems. Each of these number systems has its own unique representation and usage, and a proficient understanding of these systems is essential for the effective and accurate operation of control programs and algorithms.

Binary, the foundational system for digital data representation, is a core aspect of PLC operations, serving as the basis for all data processing and decision-making within the control environment. In addition to binary, industrial PLCs may encounter and utilize data in octal, decimal, and hexadecimal forms, each of which offers distinct advantages and applications in the representation and manipulation of control and process data. A comprehensive grasp of the principles and conversions associated with these number systems is a critical skill for PLC programmers and control system engineers, enabling them to effectively and efficiently manage the diverse and intricate data requirements of industrial automation.

Discreet and Analog I/O’s Differentiation

Within the realm of PLC control and programming, a fundamental differentiation exists between discreet and analog input and output (I/O) operations. Discreet I/O refers to the digital representation and processing of on/off or binary states, such as the activation of a switch or the detection of the presence of an object. In contrast, analog I/O encompasses the continuous representation and processing of variable signals, such as temperature, pressure, and fluid levels, which are not confined to distinct on/off states.

The effective management and programming of discrete and analog I/O operations are foundational to the seamless and comprehensive control of industrial processes. While discreet I/O tasks are characterized by binary logic and conditions, analog I/O processing involves the interpretation and manipulation of continuous data, requiring a distinct set of programming strategies and techniques. PLCs equipped with the capability to handle both types of I/O operations are essential for the versatile and holistic control of a diverse range of industrial processes, from manufacturing assembly lines to environmental monitoring and process control applications.

Input Devices and Sensors

Input devices and sensors form a critical component of PLC control systems, serving as the primary sources of data and external stimuli that the PLC uses to make control decisions. These devices can encompass a wide array of components, including proximity sensors, photoelectric sensors, pressure switches, temperature sensors, and limit switches, among others. Each of these input devices is designed to detect and report specific physical conditions or states, such as the presence or absence of an object, the level of a particular fluid, or the strength of a magnetic field.

The effective integration and configuration of input devices and sensors with PLCs are essential for the accurate and responsive control of industrial processes. Through the continuous monitoring and evaluation of the data and signals provided by these input devices, PLCs can make real-time control decisions and adjustments, ensuring the efficient and precise operation of the interconnected machinery and equipment. Furthermore, the widespread and diverse application of input devices and sensors, coupled with the critical role they play in the overall functionality of PLC-based control systems, underscores the importance of a comprehensive understanding of their operation, selection, and integration within the industrial automation environment.

Output Devices and Actuators

Complementing the input phase of PLC operations, output devices and actuators serve as the means through which the PLC exerts control and influences the connected industrial processes. These output components can encompass various actuators, such as solenoids, relays, motors, and valves, which are used to carry out specific actions and tasks in response to the control signals generated by the PLC. In addition to traditional output devices, modern industrial control systems also integrate communication interfaces, visual displays, and other advanced actuators to provide a comprehensive and versatile means of controlling and monitoring industrial processes.

The seamless integration and precise control of output devices and actuators are pivotal for the responsive and adaptive management of industrial machinery and systems. By effectively translating the control decisions and logic defined within the PLC program into tangible actions and operations, these output components enable the execution of a wide range of industrial tasks, from the automation of production processes to the control of environmental systems and the actuation of various industrial devices. A thorough understanding of the diverse types and characteristics of output devices, as well as the principles of their control and synchronization within the PLC framework, is essential for the design, programming, and maintenance of effective industrial control systems.

Basic Programming Languages

PLC programming is typically carried out using a range of specialized programming languages, each of which offers a unique set of features and advantages for different types of control and automation applications. Among the most commonly used programming languages for PLCs are ladder logic, structured text, and function block diagrams. Ladder logic, inspired by relay logic diagrams, is widely favored for its graphical representation and intuitive understanding, making it well-suited for visualizing and developing control programs in the context of industrial control systems.

Structured text, on the other hand, presents a high-level programming language that is similar to traditional programming languages, offering a rich and versatile syntax for the development of complex control algorithms and functions. Function block diagrams, characterized by their graphical representation of interconnected functions and data, provide a modular and intuitive approach to programming PLCs, particularly in the context of process control and automation. The selection of the most appropriate programming language for a specific PLC application is contingent upon various factors, including the complexity of the control tasks, the preferences of the programming team, and the specialized requirements of the industrial process being controlled, therefore necessitating a comprehensive understanding of the strengths and applications of each programming language.

Getting Started

For individuals seeking to embark on a journey into the realm of PLC programming, a systematic and structured approach to learning the fundamental concepts and practical skills is essential. Fortunately, there are abundant resources available to support the acquisition of PLC programming knowledge, ranging from formal education and training programs to self-study materials and industry certifications. Engaging in a comprehensive PLC training program can provide aspiring PLC programmers with a strong foundation in the core principles of PLC operation, programming languages, and the design and implementation of industrial control systems.

Furthermore, gaining proficiency in the use of specialized PLC programming software and tools, as well as developing hands-on experience with PLC hardware and control systems, is instrumental in cultivating the practical skills and confidence required for effective PLC programming. This can be achieved through structured training, simulation environments, and real-world projects that allow for the application and testing of PLC programming techniques in a controlled and guided manner. By leveraging a combination of theoretical knowledge, practical training, and professional exploration, individuals can establish a strong and versatile skill set in PLC programming, positioning themselves as competent and proficient contributors to the field of industrial automation and control.

In conclusion, the comprehensive mastery of PLC programming, coupled with a deep understanding of the principles of industrial control and automation, is a powerful asset for individuals and organizations operating in the dynamic and demanding landscape of modern industrial processes. With the continuous evolution and integration of PLC technology in diverse industrial applications, the proficiency in PLC programming and control system design remains a critical and highly valued competency, offering the potential for innovation, efficiency, and excellence in the realm of industrial automation.

Recommended Resources and Learning Platforms

When embarking on the path of PLC learning and proficiency, it is crucial to have access to the right resources and learning platforms that can provide valuable knowledge, practical experience, and industry-recognized certifications. The website solisplc.com serves as a comprehensive and accessible hub for individuals and professionals seeking to enhance their understanding and skills in PLC programming, offering a diverse range of online courses, tutorials, and expert guidance on various aspects of PLC control, programming languages, and industrial automation best practices. Additionally, renowned PLC manufacturers and industry organizations, such as Rockwell Automation and Siemens, offer dedicated training programs, technical resources, and certification opportunities, providing further enrichment and validation of the PLC knowledge and competence.

Exploring and engaging with these recommended resources and learning platforms can empower individuals to stay abreast of the latest advancements and emerging trends in PLC technology, while also cultivating a strong and diversified skill set in the domain of industrial automation and control. Furthermore, participating in professional networks, industry events, and collaborative projects can offer valuable opportunities for knowledge sharing, mentorship, and the practical application of PLC programming skills in real-world industrial settings, thereby fostering continuous learning and growth in this dynamic and influential field of expertise.

With the comprehensive coverage of fundamental concepts, advanced techniques, practical examples, and industry best practices, the Ultimate Guide to PLC Programming stands as a definitive and indispensable resource for individuals and professionals aspiring to excel in the realm of industrial automation and control. Through its in-depth exploration of PLC functionality, programming languages, system design, and the evolving landscape of industrial automation, this guide serves as a comprehensive companion for the continuous learning and mastery of PLC programming, equipping its readers with the knowledge, skills, and insights necessary to make impactful contributions to the dynamic and demanding world of industrial automation.

Empowered by a strong foundation in PLC programming and a deep comprehension of the integral role of PLCs in industrial automation, individuals and organizations can harness the full potential of PLC technology to drive innovation, efficiency, and safety in a diverse array of industrial processes and applications, ultimately contributing to the continuous advancement and optimization of global manufacturing and productivity.

Conclusion

In conclusion, the Ultimate Guide to PLC Programming is a comprehensive resource for both beginners and experienced professionals who are looking to enhance their automation skills. This guide covers everything from basic concepts to advanced techniques, providing readers with a deep understanding of PLC programming. By explaining the role of PLCs in manufacturing and discussing different brands and types of PLCs, this guide serves as a valuable reference for anyone looking to work with PLCs. With practical examples and tips, the Ultimate Guide to PLC Programming is accessible through the solisplc.com website and is a must-read for anyone involved in the world of automation.