The Siemens Simatic S7-300 PLC system is a versatile and reliable solution for industrial automation. In this comprehensive guide, we will explore the system’s modular architecture, programming environment, and common applications. We will also discuss maintenance and support, as well as transition options for those considering upgrading to newer systems. Whether you are new to the S7-300 or a seasoned user, this ultimate guide has everything you need to know.

Introduction

The Siemens Simatic S7-300 is a highly adaptable and modular programmable logic controller (PLC) that has earned a reputation for excellence in the field of industrial automation. With its origins dating back to 1994, the S7-300 has proven its reliability and versatility across a wide spectrum of applications, from fundamental machine control to intricate processes involved in modern manufacturing. Its continued presence in the industry underscores its integral role in the evolution of industrial automation. In this comprehensive guide, we will delve into the various facets of the Siemens Simatic S7-300, exploring its features, components, programming, applications, and much more.

This ultimate guide is designed to provide a wealth of information and insights for professionals and enthusiasts in the field of industrial automation, offering a deep understanding of the influential Siemens Simatic S7-300 and its significance in the realm of industrial automation systems. By exploring the system’s modular design, the role of its central processing unit (CPU) and input/output (I/O) modules, as well as the specialized function modules and the versatile STEP 7 software, we will unravel the intricacies that contribute to the system’s unwavering prominence in diverse industrial automation applications.

Throughout this guide, we will explore the characteristics and advantages of the S7-300, its seamless integration with a range of industrial applications, and the best practices for maintenance and support. Moreover, we will examine the transition options available, recognizing the system’s impending evolution while ensuring that its legacy and impact on the industry are duly acknowledged. The content is tailored to serve as a definitive resource for anyone seeking to deepen their understanding of the Siemens Simatic S7-300 and its enduring relevance in the rapidly advancing landscape of industrial automation.

Modular Architecture

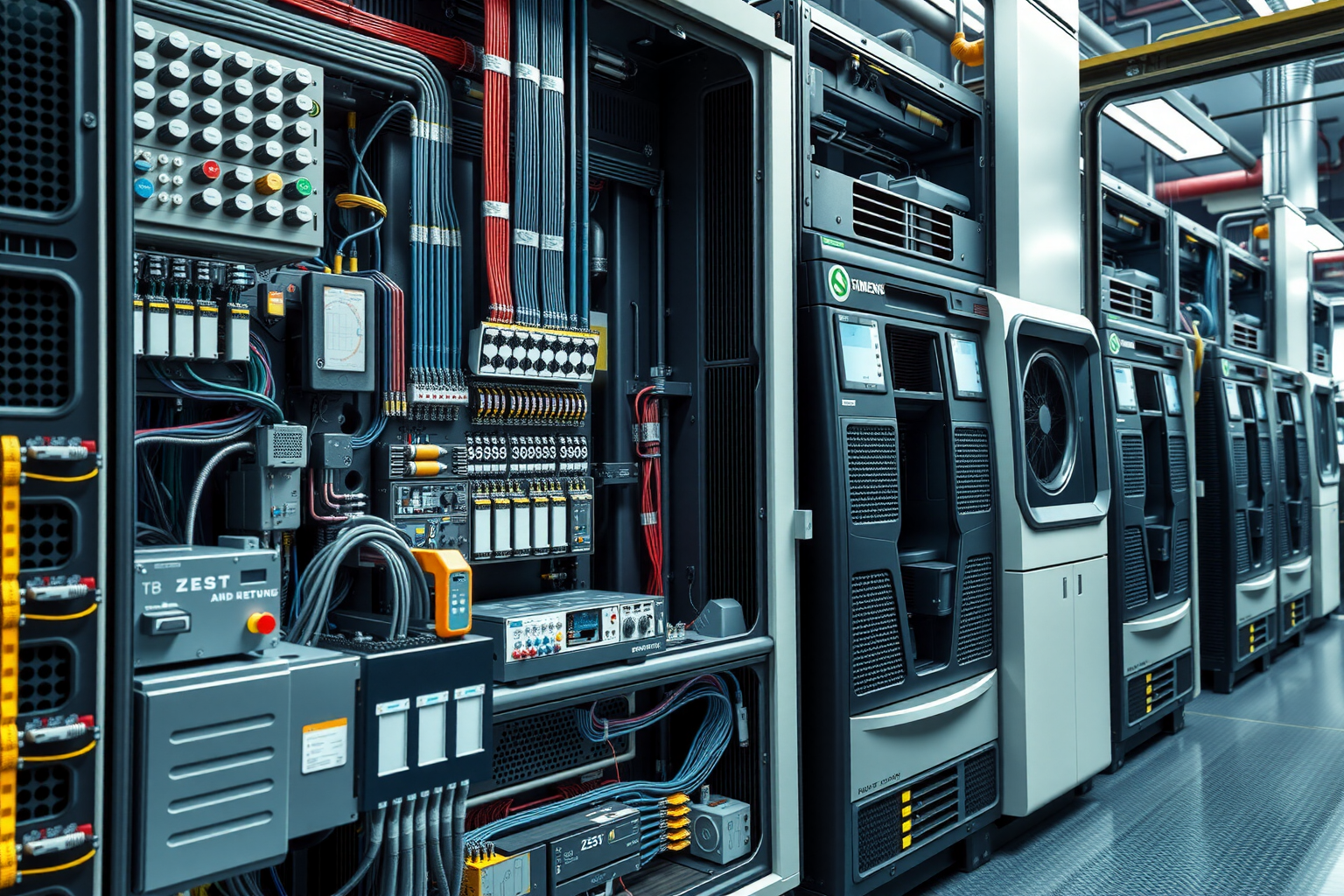

The Siemens Simatic S7-300 is inherently characterized by its modular architecture, enabling the customization of configurations to cater to specific application requirements. This modularity represents a key strength of the S7-300, as it allows for the flexibility and scalability essential to meet the diverse needs of industrial automation. By providing the freedom to select and combine various components, such as CPUs, I/O modules, and communication interfaces, the S7-300 empowers users to tailor the system to diverse tasks and industrial processes, underscoring its adaptability and versatility.

Central to the modular design of the S7-300 is the seamless integration of its individual components, ensuring that they work cohesively to form a unified and efficient automation system. The modular architecture not only streamlines the process of configuring the system to specific requirements but also simplifies the maintenance and upgrade procedures, as individual modules can be replaced or augmented with minimal disruption to the overall system. This inherent flexibility and ease of customization have solidified the S7-300’s standing as a go-to solution for a wide range of industrial automation applications.

Central Processing Unit

At the crux of the Siemens Simatic S7-300’s functionality lies its Central Processing Unit (CPU), which serves as the system’s intelligence repository and control core. The CPU is synonymous with the orchestration of the entire automation process, executing user programs, processing input data, and exerting control over the output devices. Equipped with robust processing capabilities and a real-time operating system, the CPU effectively manages the communication between the various components of the S7-300, thereby ensuring seamless coordination and synchronization in executing complex automation tasks.

Furthermore, the CPU plays a pivotal role in the system’s diagnostic and monitoring capabilities, leveraging its computational prowess to conduct comprehensive system diagnostics and fault identification. This intrinsic ability reinforces the system’s reliability and minimizes downtime by promptly addressing and troubleshooting any malfunctions or discrepancies. In the context of industrial automation, where operational continuity and precision are paramount, the CPU’s operational acumen is indispensable, rendering the S7-300 an indispensable asset in a multitude of industrial scenarios.

I/O Modules

The Input/Output (I/O) modules are integral constituents of the Siemens Simatic S7-300, forming the crucial interface that facilitates the interaction between the PLC and the external world. By seamlessly connecting the PLC to various field devices, sensors, and actuators, the I/O modules empower the system to perceive and influence the industrial environment. Whether it involves acquiring data from sensors, executing control commands to connected actuators, or relaying operational feedback, the I/O modules underpin the S7-300’s capacity to govern and monitor a diverse array of processes and equipment.

Leveraging a modular approach, each I/O module within the S7-300 can be custom-configured to accommodate distinct types of signals, such as digital, analog, or high-speed counter inputs, as well as various communication protocols. This adaptability not only underscores the I/O modules’ pervasive utility across different industrial sectors but also furnishes the S7-300 with the intelligence and reactivity requisite for diverse automation tasks. Whether in manufacturing, process control, or equipment monitoring, the seamless integration and reliability of the I/O modules are pivotal in ensuring the efficacy and precision of the S7-300 PLC in real-world industrial deployments.

Special Function Modules

Complementing the standard I/O modules, the Siemens Simatic S7-300 avails a spectrum of specialized function modules, each engineered to address distinct facets of contemporary industrial automation. These function modules, which encompass provisions for motion control, communication, safety, and other domain-specific functions, fortify the S7-300’s adaptability and enrichment beyond conventional I/O capabilities. By affording seamless integration and dedicated processing for specialized tasks, these modules empower the S7-300 to address the increasingly nuanced and diverse requirements of modern industrial applications.

Whether it entails the implementation of advanced motion control functions, ensuring robust and secure industrial communication, or instituting safety protocols for personnel and machinery, the special function modules augment the S7-300’s operational repertoire to encompass a comprehensive array of tasks. This multifaceted approach not only bolsters the system’s responsiveness and intelligence in addressing diverse industrial challenges but also underscores its innate ability to adapt and evolve in accordance with the dynamic imperatives of the industrial automation landscape. The strategic integration of these specialized function modules cements the S7-300’s position as a dynamo in the domain of modern industrial automation, catering to a spectrum of operational exigencies with unparalleled efficacy.

STEP 7 Software

The Siemens Simatic S7-300 is underpinned by the robust and versatile STEP 7 software, which constitutes a cornerstone of the system’s programming, configuration, and diagnostic ecosystem. Functioning as a centralized environment for the conception, testing, and deployment of control programs, STEP 7 empowers users with comprehensive tools and functionalities that streamline the development process and fortify the system’s operational integrity. By seamlessly integrating the facets of program development, system configuration, and diagnostic appraisal, STEP 7 catalyzes an efficient and cohesive approach to orchestrating the diverse dimensions of the S7-300’s operational intricacies.

Furthermore, the STEP 7 software’s multifaceted programming environment accommodates diverse programming languages, thereby ensuring that users can leverage the linguistic constructs best aligned with their operational preferences and application mandates. Whether it entails the expeditious formulation of control programs in Ladder Diagram (LAD) format, the employment of structured programming paradigms in Function Block Diagram (FBD) format, or the delineation of high-level logic operations in Statement List (STL) format, the STEP 7 software’s inclusive and flexible programming ecosystem coalesces to furnish users with the autonomy and versatility to operationalize their unique automation design imperatives.

Multiple Languages

Emphasizing its commitment to fostering an inclusive and user-centric approach, the Siemens S7-300 seamlessly integrates support for multiple programming languages within the STEP 7 software environment. By accommodating renowned standards such as Ladder Diagram (LAD), Function Block Diagram (FBD), and Statement List (STL), the S7-300’s programming interface resonates with the linguistic preferences and proficiencies of a diverse global user base. This linguistic inclusivity not only diminishes barriers to entry for individuals and organizations adept in variegated programming paradigms but also cultivates a collaborative and knowledge-sharing ecosystem within the broader community of industrial automation professionals.

Moreover, by endowing its users with the latitude to select and leverage the programming language best attuned to their operational inclinations and application-specific exigencies, Siemens orchestrates an environment conducive to innovation, creativity, and enhanced productivity. This discerning attunement to the diverse linguistic proclivities and technical exactitudes within the industrial automation domain fortifies the S7-300’s standing as an epitome of inclusivity, flexibility, and heightened operational efficacy, catering to a global tapestry of user requirements and preferences.

Common Applications

The Siemens Simatic S7-300 manifests its prowess across an eclectic spectrum of industrial applications, permeating diverse sectors and operational domain where precision, reliability, and adaptability are sine qua non. Whether it entails the orchestration of manufacturing processes, the meticulous governance of complex industrial systems, or the implementation of seamless communication and control protocols, the S7-300 establishes its imprint across a multitude of operational landscapes. Its innate capacity to orchestrate and regulate diverse industrial processes renders it a linchpin in contemporary industrial automation, as it interfaces with and transforms a myriad of operational facets into cohesive, efficient, and intelligent systems.

Moreover, the S7-300’s pervasive applicability extends to the realm of infrastructure projects, testimonial to its versatility and adaptive synergy with a broad swath of industrial imperatives, as it governs and regulates essential utilities and infrastructure that underpin the fabric of modern society. Whether it entails the management of energy distribution networks, the regulation of essential public transportation systems, or the oversight of critical utility infrastructures, the S7-300 asserts its ingenuity and reliability in providing seamless automation and control, thereby underscoring its ubiquitous relevance in the industrial landscape.

Manufacturing, Process Control, Building Automation

The Siemens Simatic S7-300 is inextricably linked with the domains of manufacturing, process control, and building automation, as it permeates each of these sectors with its adaptability, reliability, and potent operational capabilities. In the realm of manufacturing, the S7-300 orchestrates the control of assembly lines, the regulation of packaging machinery, and the seamless integration of diverse operational modules, thereby fostering enhanced productivity, precision, and operational coherence. Within the sphere of process control, the S7-300 assumes a pivotal role in managing and orchestrating operations in chemical plants, power generation facilities, and water treatment establishments, thereby ensuring the seamless and reliable execution of critical industrial processes.

In the context of building automation, the S7-300 extends its trajectory into overseeing essential systems such as heating, ventilation, and air conditioning (HVAC), lighting, and security, thereby underpinning the infrastructure of modern edifices with its adaptability, intelligence, and robust operational capabilities. This seamless integration of the S7-300 into the trio of manufacturing, process control, and building automation epitomizes its formative influence and pervasive impact in orchestrating and regulating a spectrum of industrial and infrastructural processes, fortifying its eminence as an indispensable linchpin in the contemporary industrial automation milieu.

Maintenance and Support

The maintenance and support of the Siemens Simatic S7-300 are foundational to ensuring its sustained operational integrity and long-term reliability within an array of industrial applications. By instituting regular maintenance protocols, conducting comprehensive system diagnostics, and adhering to proactive troubleshooting practices, industrial entities can uphold the S7-300’s operational efficacy and longevity, thereby mitigating unanticipated downtime and optimizing system performance. Additionally, by capitalizing on the diagnostic tools and maintenance functionalities integrated within the STEP 7 software, users can ascertain and address potential issues preemptively, obviating the escalation of concerns and bolstering the overall resilience and robustness of the system.

Moreover, Siemens extends a comprehensive suite of support services, encompassing training programs, technical documentation, and access to a global network of service centers, thereby fortifying the post-deployment assistance and operational learning avenues for users of the S7-300. This steadfast commitment to availing users with the requisite knowledge, resources, and technical guidance not only amplifies the overall ownership experience and operational acumen of the S7-300 but also reinforces the system’s standing as a perpetually evolving and supported component within the broader tapestry of industrial automation solutions.

Transition Options

Recognizing the dynamic and evolving landscape of industrial automation, Siemens has instituted transition options and migration tools to facilitate the seamless evolution from the S7-300 to newer PLC families such as the S7-1200 and S7-1500. These transition avenues, underpinned by comprehensive documentation and user support, are designed to empower users with the insights, procedures, and technical acumen necessitated to effectuate a smooth migration, while minimizing operational disruptions and optimizing the utilization of today’s advanced and future-ready automation solutions. Moreover, by showcasing the compatibility of the STEP 7 software with the S7-1200 and S7-1500, Siemens affirms the continuity of users’ programming proficiencies and project assets, engendering a sense of reassurance and effectiveness in navigating the path towards newer and more evolved industrial automation paradigms.

Furthermore, by reiterating the continued availability of support and spare parts for the S7-300 until 2033, Siemens underscores its unwavering commitment to upholding the operational sanctity and operational continuity of the S7-300, while concurrently extending a conducive runway for users to strategically orient and evolve their automation strategies towards contemporary and future-ready paradigms. This strategic continuum of support and the provision of comprehensive transition options galvanize the S7-300’s standing as a resilient and reliable solution within the broader mosaic of industrial automation, underlining its enduring relevance and influence in the ever-evolving industrial landscape.

Introduction to the S7-300 PLC System

The Siemens Simatic S7-300 PLC system, with its robust heritage, modular adaptability, and comprehensive operational capabilities, stands as a ubiquitous force within the domain of industrial automation. Its trajectory traverses a spectrum of industrial landscapes, attesting to its transformative impact and omnipresence in the orchestration and governance of contemporary industrial processes. As we navigate through the intrinsic facets and operational nuances of the S7-300, it becomes evidently apparent that its legacy as a vanguard of reliability, adaptability, and operational acumen remains unabated, underscoring its pivotal role as a harbinger of industrial automation excellence. Whether it entails the orchestration of manufacturing processes, the regulation of complex system interfaces, or the governance of diverse industrial applications, the S7-300 asserts its legacy as an indispensable catalyst in the seamless evolution and orchestration of modern industrial automation.

By underpinning its operational domain with a modular architecture, a potent central processing nucleus, versatile I/O modules, and an array of specialized function modules, the S7-300 orchestrates a cohesive and streamlined operational ethos that reverberates through the annals of diverse industrial processes and automation paradigms. Moreover, by offering a comprehensive programming ecosystem, inclusive of diverse programming languages and integrated diagnostic tools, the S7-300 augments the realms of system development, maintenance, and optimization, underscoring its integral role as a harbinger of operational intelligence and technological advancement in the sphere of industrial automation. The S7-300’s multifaceted applications, encompassing manufacturing, process control, and building automation, bespeak its pervasive impact and seamless integration into the broader tapestry of industrial imperatives, fortifying its eminence as a resilient and adaptable anomaly within the realm of contemporary industrial automation solutions. With a steadfast commitment to operational excellence, comprehensive user support, and transition facilitation, the S7-300 embodies the quintessence of industrial automation par excellence, perpetuating a legacy of innovation, reliability, and seamless integration within the ever-evolving global industrial landscape.

Conclusion

Given the Siemens SIMATIC S7-300 is a versatile and reliable programmable logic controller system that has been used in various industries since its introduction in 1994. With its modular architecture, comprehensive programming environment, and extensive support network, the S7-300 is a valuable solution for industrial automation needs. Despite newer PLC options, the S7-300 remains a viable choice for many applications and offers a smooth transition path for users considering an upgrade.