Introducing the ultimate guide to PLC control panels – your go-to resource for everything you need to know about these critical components in industrial automation. From understanding the key components to considerations for design and layout, we will cover it all. Prepare to gain a comprehensive understanding of PLC control panels and their applications in various industries as well as future trends in this evolving technology. Let’s dive in!

What is a PLC Control Panel?

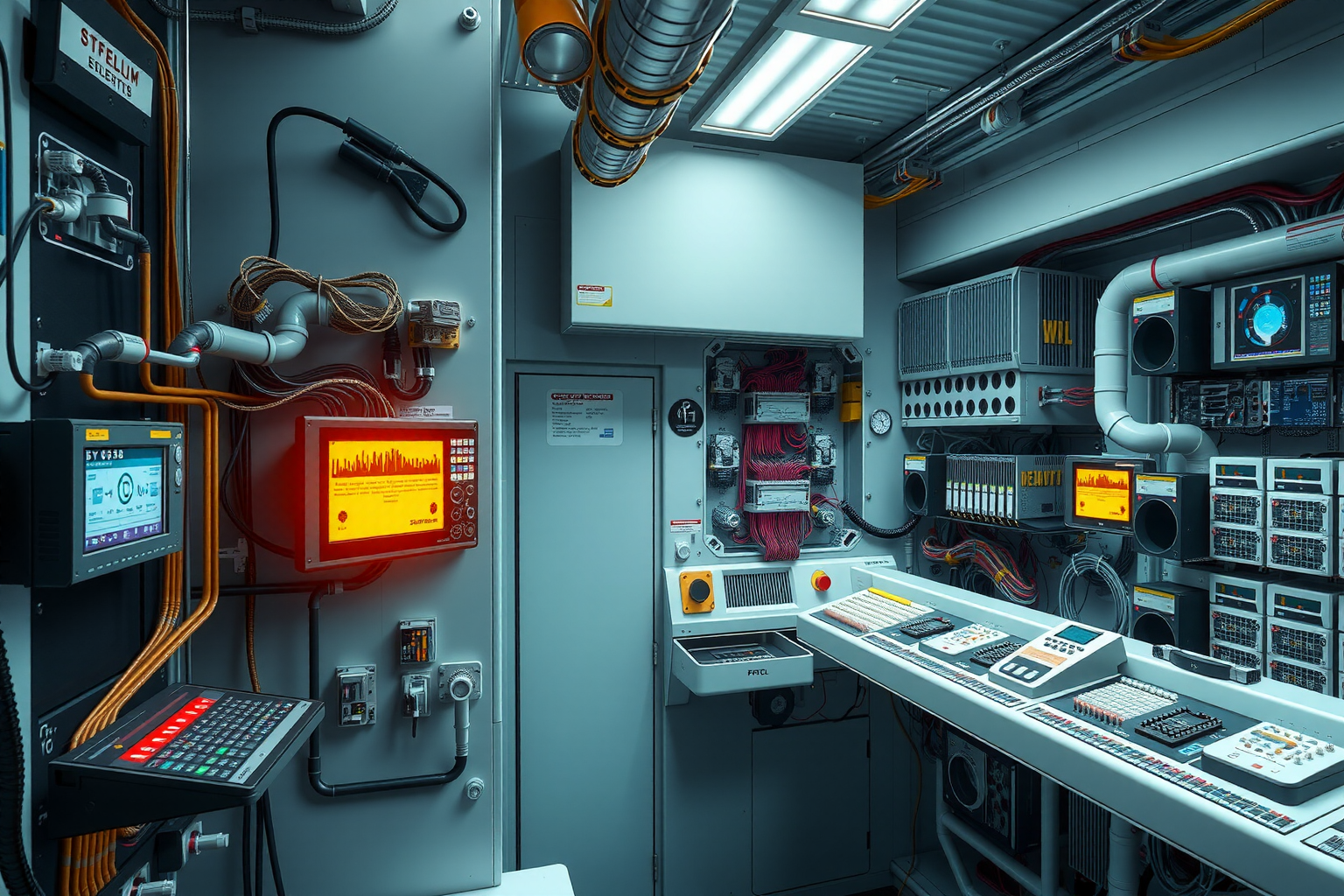

At its core, a Programmable Logic Controller (PLC) control panel is a sophisticated electronic system that plays a pivotal role in the realm of industrial automation. These meticulously designed panels serve as the central intelligence for a myriad of automated systems, acting as the command hub that oversees and orchestrates the operation of machinery and various industrial processes. By executing a diverse range of tailored instructions through programmatic logic, PLC control panels usher in a new era of precision, efficiency, and reliability in the control and monitoring of industrial processes, ranging from simple conveyor systems to complex manufacturing operations.

Integral to the concept of the PLC control panel is the Programmable Logic Controller itself, a versatile computing device specifically tailored for real-time industrial control. The PLC, with its ability to continuously monitor input device status and make decisions based on pre-defined logic, forms the crux of these control panels, making them indispensable in the domain of industrial automation. The seamless integration of hard-wired control systems with the PLC not only expedites the processing of signals from a wide array of sensors and input devices but also ensures the efficient management of output devices, thereby exerting a substantial impact on overall operational efficiency and system responsiveness.

Furthermore, the comprehensive PLC control panel encapsulates various other essential elements, including the electrical panel, which serves as a pivotal interface for the power supply and acts as a dedicated housing for crucial electrical components. The synergistic functioning of the PLC and the electrical panel culminates in the coherent management of the power supply to the connected devices and the seamless execution of control commands, thus establishing a cohesive and robust control and monitoring infrastructure within the industrial ecosystem.

Key Components

Delving into the intricacies of a typical PLC control panel reveals an assemblage of integral components that collaboratively underpin its functionality and efficacy. These components form the cornerstone of the panel’s design and operation, each contributing a distinct yet interconnected role in the overall control and monitoring process. From the central processing unit to input/output modules and the human-machine interface, the amalgamation of these components bolsters the reliability, scalability, and adaptability of the PLC control panel.

Processor

Central to the operational framework of a PLC control panel is the PLC processor, which assumes a pivotal role in executing the control programs and processing the input signals. Operating as the brain of the system, the processor interprets the signals received from various input devices and implements the corresponding control logic to generate appropriate output commands. This dynamic interplay of data processing and control execution not only facilitates the seamless coordination of connected devices but also enables the panel to respond to real-time process variations and contingencies with agility and precision.

Input/Output (I/O) Modules

The input/output (I/O) modules constitute a core facet of the PLC control panel, serving as the crucial interface between the PLC and the external devices. These modules facilitate the acquisition of input signals from various sensors, switches, and other connected devices while simultaneously orchestrating the transmission of output signals to actuate motors, valves, and other end devices. By establishing a seamless conduit for bidirectional communication, the I/O modules play a fundamental role in ensuring the PLC’s continuous interaction with the external environment, thereby fostering a cohesive and synchronized control ecosystem.

Power Supply

The power supply unit integrated within the PLC control panel assumes the critical responsibility of delivering a stable and reliable electrical supply to the various panel components. This dedicated power provision, essential for the uninterrupted operation of the PLC, I/O modules, and other associated elements, underpins the overall functionality and reliability of the control panel. Moreover, the power supply unit must be meticulously designed to ensure protection against power surges, fluctuations, and other electrical irregularities, thereby safeguarding the panel’s internal components and sustaining the integrity of the entire control system.

Human-Machine Interface (HMI)

The human-machine interface (HMI) component forms a pivotal conduit between the operational personnel and the control panel, enabling intuitive and user-friendly interaction with the system. Through visual displays, touchscreens, and input peripherals, the HMI facilitates real-time monitoring, data visualization, and manual control of the connected processes, thereby fostering an interactive and responsive operational environment. The incorporation of advanced HMI technologies not only augments the panel’s usability and visual appeal but also empowers the operators with enhanced control and monitoring capabilities, ushering in a new paradigm of operational efficiency and workflow optimization.

Communication Interfaces

The communication interfaces embedded within the PLC control panel serve as the conduits for seamless data exchange and coordination with external systems, including supervisory control and data acquisition (SCADA) platforms and other interconnected PLCs. By establishing robust and flexible communication channels, such as Ethernet, serial, and wireless interfaces, the panel orchestrates an efficient flow of operational data, remote access, and centralized control, thereby engendering a cohesive and interconnected industrial control environment. This heightened interconnectivity, underpinned by the communication interfaces, not only enhances the panel’s overall functionality and scalability but also paves the way for advanced monitoring, diagnostics, and remote operability.

Design and Layout

The design and layout of a PLC control panel bear enormous significance in determining its operational efficiency, safety, and maintainability. A meticulously conceived and executed design paradigm, encompassing structural layout, component allocation, and wiring organization, is indispensable for optimizing the panel’s functionality and ensuring seamless integration within a broader industrial infrastructure. By adhering to stringent design principles and best practices, the control panel can be tailored to offer a robust, space-efficient, and user-friendly operational interface, while also facilitating systematic expansion and retrofitting to meet evolving industrial demands.

Component Grouping

A fundamental design consideration revolves around the strategic grouping of panel components based on their functional characteristics, operational voltage levels, and electromagnetic compatibility. By categorizing interconnected devices into designated zones, such as power distribution, control circuitry, and communication interfaces, the control panel can mitigate the risk of interference, cross-talk, and signal degradation, thereby fostering a stable and harmonious operational environment. Furthermore, the systematic grouping of components not only streamlines installation and troubleshooting processes but also engenders a well-organized and visually discernible paneled layout, enhancing operational clarity and accessibility.

Space Allocation

The judicious allocation of space within the PLC control panel is pivotal in ensuring unobstructed workflow, systematic cable management, and the provision of adequate cooling and ventilation. By meticulously planning and reserving sufficient real estate for individual components and future expansion provisions, the panel design can avert congestion, heat buildup, and accessibility concerns, thereby engendering a conducive and ergonomic operational environment. Moreover, a well-optimized spatial layout not only safeguards the panel against external environmental influences but also upholds the principle of compartmentalization, thereby minimizing the propagation of potential faults and disruptions within the system.

Wire Management

Effective wire management, encompassing organized routing, bundling, and labeling practices, is essential for upholding the operational integrity and safety of the control panel. By implementing structured wiring methodologies, such as deploying cable ducts, trays, and segregation protocols, the panel can mitigate the risk of electromagnetic interference, signal crosstalk, and accidental damage, thereby fortifying the overall reliability and maintainability of the electrical infrastructure. Furthermore, systematic labeling and documentation of wiring connections and terminations not only streamline troubleshooting and maintenance operations but also serve as a valuable reference for future expansions and operational modifications.

Grounding

The establishment of a robust and systematic grounding infrastructure within the PLC control panel is imperative for mitigating the risks of electrical faults, surge-induced damage, and interference effects. By instituting a comprehensive grounding network, encompassing single-point grounding, equipotential bonding, and grounding conductors, the panel design can avert the manifestation of ground loops, stray currents, and potential differences, thereby fostering a stable and secure operational environment. Moreover, the incorporation of industry-compliant grounding methodology not only upholds the principles of electrical safety and EMC (electromagnetic compatibility) compliance but also reinforces the overall resilience and electromagnetic immunity of the control panel.

Benefits of PLC Control Panels

The implementation of PLC control panels bestows a myriad of compelling advantages that collectively underpin the transformative impact of these systems on industrial automation and process control. From the enhancement of operational efficiency to the facilitation of adaptive control and centralized monitoring, the comprehensive benefits of PLC control panels resonate across diverse industrial sectors, redefining the paradigms of productivity, reliability, and operational flexibility.

Enhanced Productivity

By automating and orchestrating a diverse array of complex industrial tasks and processes, PLC control panels serve as the primary catalysts for elevating productivity and operational throughput. Their ability to execute precise control logic, monitor process variables in real time, and expedite decision-making and actuation mechanisms culminates in streamlined production, minimized downtime, and optimized resource utilization, thereby galvanizing overall operational efficiency and output consistency.

Flexibility and Adaptability

PLCs, with their reprogramming capabilities and versatile control functionalities, empower industries with unparalleled flexibility and adaptability to rapidly changing operational requirements and production volatilities. Whether it pertains to accommodating design changes, modulating sequence parameters, or integrating new machinery into existing control infrastructures, the inherent flexibility of PLC control panels equips industries with the agility to swiftly and seamlessly realign their operations while upholding stringent quality and performance standards.

Reliability and Fault Tolerance

Designed to withstand the rigors of demanding industrial environments, PLC control panels exude a robust and fault-tolerant operational demeanor, thereby engendering unwavering reliability and longevity over extended operational periods. Their systematic fault diagnosis, redundancy mechanisms, and proactive error handling capabilities minimize the occurrences of unscheduled downtimes, system failures, and performance anomalies, thereby safeguarding the operational continuity and overall productivity of the integrated industrial processes.

Scalability and Expansion

The inherent scalability and modularity of PLC control panels confer upon industries the ability to proportionately expand their control and monitoring infrastructure to accommodate evolving operational demands and burgeoning production capacities. Whether it involves the integration of additional I/O modules, communication interfaces, or interlinked PLCs, the scalable architecture of PLC control panels engenders a future-proof and adaptive control environment, laying the groundwork for seamless expansion and capability augmentation to align with dynamic industrial requirements.

Applications Across Industries

The pervasive influence and multifaceted capabilities of PLC control panels reverberate across an extensive spectrum of industrial domains, undergirding and revolutionizing the operational paradigms of diverse sectors. Whether in manufacturing, process control, or building automation, the applications of PLC control panels bear testament to their integral role in fostering efficiency, reliability, and precision in a myriad of industrial contexts.

Manufacturing Automation

Within the manufacturing domain, PLC control panels orchestrate the automation and control of assembly lines, material handling systems, and CNC (computer numerical control) machinery, thereby propelling productivity, precision, and operational consistency. From regulating machining operations to coordinating robotic interventions and custom manufacturing workflows, PLC control panels serve as the linchpin of modern manufacturing ecosystems, undergirding the seamless integration and synchronization of diverse manufacturing processes.

Chemical Processing

In chemical processing facilities, PLC control panels are instrumental in orchestrating the intricate control and monitoring of chemical reactors, batch processing sequences, and continuous flow processes. By orchestrating the synergistic interplay of diverse process parameters, such as temperature, pressure, and flow rates, these control panels ensure the safety, consistency, and optimal efficiency of chemical production and processing operations, mitigating the risks of anomalies and deviations in critical chemical reactions and transformations.

Food and Beverage Production

The stringent adherence to hygiene, quality, and process control in the food and beverage industry finds a formidable ally in PLC control panels, which oversee the automation and monitoring of packaging, processing, and distribution systems. Whether in regulating pasteurization processes, synchronizing bottling lines, or maintaining ambient environmental conditions, PLC control panels insulate against the perils of contamination, variability, and inefficiency, thereby upholding the sanctity and consistency of food and beverage production and delivery processes.

Automotive and Transportation

Within the automotive sector, PLC control panels undergird the orchestration of assembly line operations, material handling systems, and robotic interventions, underpinning the precision, agility, and scalability integral to modern automotive manufacturing. By coordinating the interplay of diverse production stations, sequential operations, and mechanized interventions, PLC control panels fuel the evolutionary paradigm of automotive manufacturing, imbuing it with the attributes of precision, speed, and adaptability requisite for meeting dynamic market demands and technological advancements.

Building Automation and HVAC Control

Embracing the realm of building automation, PLC control panels assume the mantle of orchestrating HVAC (heating, ventilation, and air conditioning) systems, lighting controls, and facility management interfaces, thereby optimizing energy consumption, occupant comfort, and operational efficiency within diverse built environments. By harmonizing climate control, lighting scenarios, and occupancy patterns, PLC control panels usher in an era of intelligent and adaptive building management, conferring upon the edifices a degree of operational finesse and efficiency hitherto unparalleled in traditional building automation paradigms.

Future Trends in PLC Control Panels

The dynamic landscape of industrial automation and control technologies bears witness to a continuum of evolutionary advancements that are poised to redefine the frontiers of PLC control panels, ushering in a new era of integration, intelligence, and cybersecurity. As the industrial ecosystem gravitates towards an increasingly interconnected, intelligent, and robust operational paradigm, the future trajectory of PLC control panels is intrinsically interwoven with the realization of these transformative advancements.

Integration with Industrial IoT (IIoT)

The confluence of PLC control panels with the realm of industrial IoT not only engenders a paradigm shift in connectivity and data utilization but also propels the notion of remote monitoring, predictive maintenance, and advanced data analytics into the archetype of modern industrial control. By converging with IIoT frameworks, PLC control panels unfurl a prelude to a new era of operational intelligence, enabling real-time condition monitoring, asset tracking, and data-driven decision-making, thereby rewriting the operational playbook of diverse industrial sectors.

Incorporation of Artificial Intelligence (AI) and Machine Learning (ML)

The infusion of AI and ML paradigms within the operational milieu of PLC control panels begets an intelligence-driven and autonomously optimizable control infrastructure, capable of discerning patterns, forecasting operational contingencies, and autonomously adapting control strategies to align with evolving process dynamics. By harnessing the predictive and prescriptive capabilities of AI and ML, PLC control panels usher in an epoch of cognitive and self-optimizing industrial control, redefining the contours of efficiency, reliability, and decision-making autonomy within industrial processes.

Enhanced Cybersecurity Measures

The burgeoning interconnectivity and network integration of PLC control panels accentuate the quintessential need for fortified cybersecurity measures to preempt and mitigate the perils of cyber threats and vulnerabilities. As PLC control panels seamlessly interface with broader networked landscapes, the robust fortification of communication protocols, access controls, and anomaly detection paradigms emerges as a cardinal imperative, underpinning the sanctity, confidentiality, and uninterrupted operability of critical industrial control infrastructure amidst an evolving tapestry of cyber threat landscapes.

In conclusion, the realm of PLC control panels stands at the nexus of convergence between cutting-edge technology and the evolving imperatives of industrial automation, orchestrating a metamorphic journey towards an era of unbounded efficiency, intelligence, and interconnected operability. With their ingrained versatility, adaptability, and transformative impact across diverse industrial sectors, PLC control panels emerge as the vanguards of a new industrial renaissance, underpinned by the fulcrum of innovation, integration, and operational excellence.

Conclusion

In conclusion, PLC control panels are essential components in modern industrial automation, providing precise control and monitoring of complex processes. By understanding the key components and design considerations, as well as keeping up with technological advancements, industries can fully harness the benefits of PLC control panels to increase productivity, flexibility, and reliability.