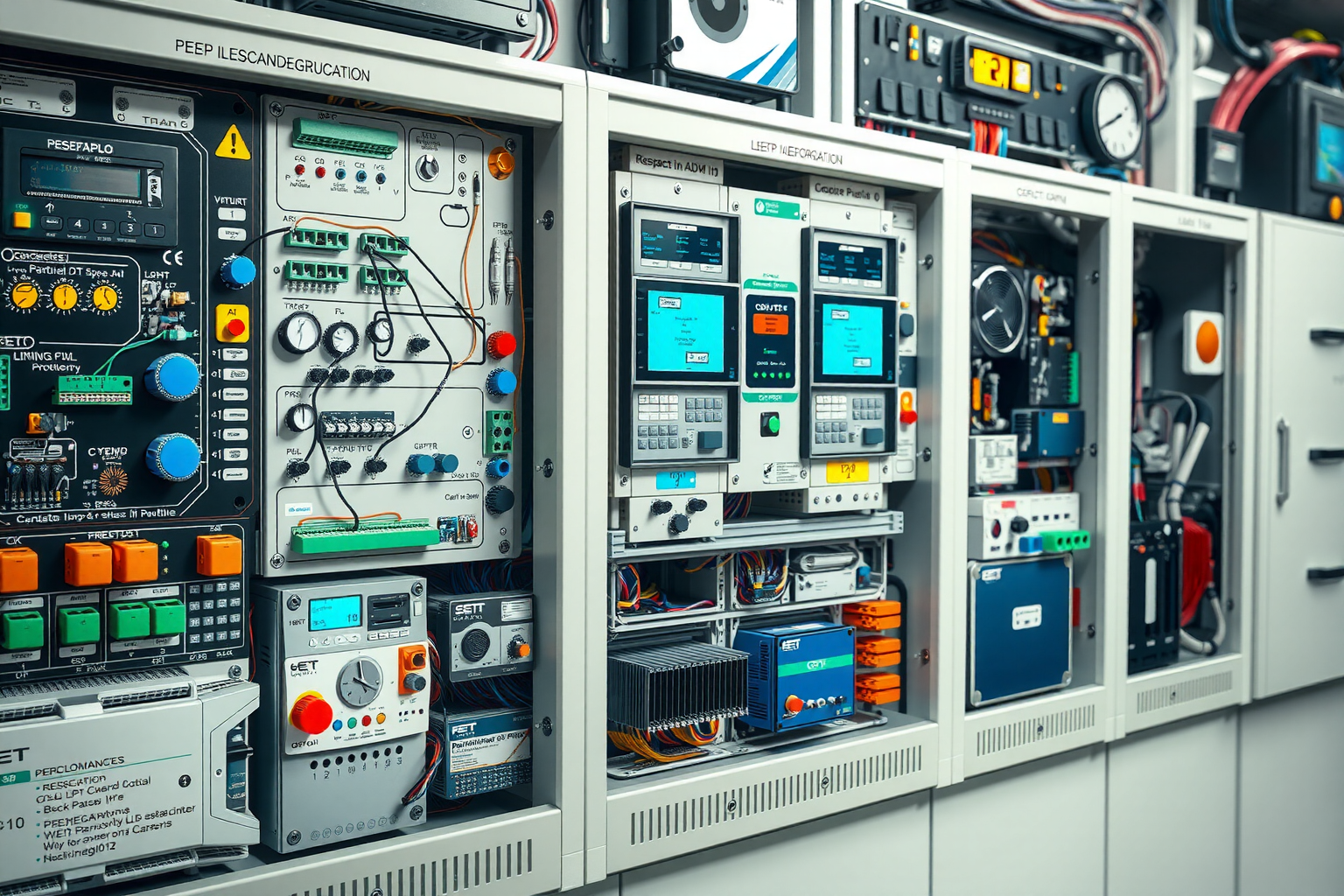

of the articles are being copied.If you work in industrial automation, chances are you have encountered a PLC panel at some point. This essential component plays a significant role in controlling and monitoring machinery and processes in various industries. In this guide, we will dive into the world of PLC panels, exploring their structure, components, functions, installation, and maintenance. Whether you are new to PLCs or looking to deepen your knowledge, this article aims to provide everything you need to know about PLC panels.

Key Components of a PLC Panel

When it comes to industrial automation and process control, the Programmable Logic Controller (PLC) panel is a central and crucial component. Its sophisticated structure is comprised of several integral parts, each playing a significant role in ensuring the seamless operation and control of various industrial processes and machinery. Understanding these key components is essential for anyone involved in the field of industrial automation.

A typical PLC panel consists of several fundamental elements that work in harmony to execute the control and monitoring functions. One of the most critical components is the Power Supply, responsible for converting the incoming electrical power, whether alternating current (AC) or direct current (DC), into the specific voltage and current levels required by the various devices within the control panel. This ensures a consistent and reliable power distribution, which is vital for the panel’s overall performance.

The Central Processing Unit (CPU), often referred to as the brain of the PLC, is another essential component of the panel. It interprets the inputs, executes control programs stored in its memory, and manages the outputs, thereby playing a central role in the panel’s operation. Apart from these, the Input/Output (I/O) Modules are crucial for establishing communication between the PLC and external devices. These modules receive signals from sensors and switches, converting them into digital signals for processing, while the output modules send control signals to actuators and other output devices.

Furthermore, the Memory component of a PLC panel plays a vital role in storing the control program and essential data. It typically includes Random Access Memory (RAM) for temporary storage and Read-Only Memory (ROM) for permanent storage, ensuring that the CPU has access to the instructions and information necessary for the execution of control functions. Lastly, the Communication Interface facilitates the integration of the PLC with other systems and devices, allowing for seamless data exchange and connectivity with external control and monitoring systems.

Power Supply

The Power Supply module within a PLC panel is the lifeblood of the system, responsible for ensuring that the panel and its various components receive a reliable and consistent source of power. Its primary function is to convert the incoming electrical power, which can be in the form of alternating or direct current, into the specific voltage and current levels required by the different devices and modules within the panel. This is a critical function, as any fluctuations or interruptions in the power supply can directly impact the performance and reliability of the entire control system.

Moreover, the Power Supply module also plays a role in implementing essential safety measures, such as overvoltage and overcurrent protection, to safeguard the panel and its components from electrical anomalies. By maintaining a stable and secure power environment, the Power Supply module is indispensable in ensuring the continuous and trouble-free operation of the PLC panel and the connected industrial processes and equipment.

Central Processing Unit (CPU)

The Central Processing Unit (CPU) serves as the beating heart of a PLC panel, orchestrating and executing a multitude of complex tasks essential for the effective control and monitoring of industrial processes. Its primary function is to receive inputs from various devices and sensors, execute the control program, and manage the outputs, thereby functioning as the brain behind the panel’s operation. The CPU is responsible for executing logical operations, sequencing tasks, and coordinating the entire control process, making it a pivotal component in the overall performance of the PLC panel.

Furthermore, the CPU plays a crucial role in implementing essential safety and monitoring functions, such as identifying and responding to abnormal conditions or process alarms, ensuring the protection of both the machinery and the surrounding environment. With its capacity to handle a wide range of complex tasks and make real-time decisions, the CPU is undoubtedly the powerhouse of the PLC panel, driving the entire control and automation system with precision and efficiency.

Its robust processing capabilities and versatility make the CPU an indispensable element in various industrial applications, ranging from manufacturing and energy production to transportation and building automation, where precise and adaptive control is paramount.

Input/Output (I/O) Modules

The Input/Output (I/O) Modules are the essential conduits of a PLC panel, facilitating the seamless exchange of information and control signals between the panel and the external world. These modules are responsible for receiving input signals from various devices, such as sensors, switches, and transducers, and converting them into digital signals that can be processed by the CPU. On the other hand, they also take digital signals from the CPU and convert them into control signals for output devices, including actuators, relays, and other control elements.

By serving as the interface between the PLC and the external environment, the I/O Modules play a critical role in the real-time control and monitoring of industrial processes. They enable the panel to respond to external stimuli, implement control commands, and relay imperative information to and from the connected devices. This bidirectional communication is essential for the precise and responsive operation of automated systems, making the I/O Modules a cornerstone of industrial control and automation.

Memory

The Memory component of a PLC panel is a sophisticated and versatile subsystem that serves as the repository for the control program, essential data, and intermediate results. It is typically comprised of multiple tiers, including Random Access Memory (RAM), which provides temporary storage for the CPU’s operational data, and Read-Only Memory (ROM), which permanently stores the control program and crucial system parameters. This dual-layer structure enables the panel to execute real-time control logic and retain essential information even during power outages or system resets.

In addition to program and data storage, the Memory subsystem also accommodates the execution of complex mathematical calculations, data processing, and the maintenance of internal diagnostics and status variables. Its ability to manage and retain critical information in a reliable and efficient manner is fundamental to the overall functionality and performance of the PLC panel, ensuring consistent control and system stability.

Communication Interface

The Communication Interface of a PLC panel acts as the digital nerve center, facilitating the seamless exchange of data, commands, and status information between the panel and other systems or devices. It enables the PLC to interface with external components, such as Human-Machine Interfaces (HMIs), Supervisory Control and Data Acquisition (SCADA) systems, and other PLCs, using standard communication protocols and network interfaces. This connectivity and interoperability are crucial for the integration and orchestration of complex industrial processes, allowing for centralized control, data sharing, and system coordination.

Moreover, the Communication Interface also plays a pivotal role in enabling remote monitoring and control, as well as the implementation of advanced automation strategies, such as distributed control systems and Internet of Things (IoT) connectivity. By extending the PLC panel’s reach and capability beyond its immediate boundaries, the Communication Interface contributes significantly to the realization of intelligent and interconnected industrial automation solutions, enhancing visibility, flexibility, and operational efficiency.

Functions of a PLC Panel

Within the realm of industrial control and automation, the functions of a Programmable Logic Controller (PLC) panel are as diverse as they are critical to the smooth and efficient operation of industrial processes. From signal processing to data management and system integration, the PLC panel serves as the linchpin of industrial control, performing a wide range of essential functions that underpin the reliability, safety, and performance of automated systems.

One of the primary functions of a PLC panel is the handling of both analog and digital Input/Output (I/O) signals. This capability enables the panel to process a diverse array of input signals from sensors and transducers, as well as to control various output devices, such as motors, valves, and relays, with precision and responsiveness. By managing both discrete and continuous signals, the PLC panel ensures comprehensive control over a wide range of industrial processes, from discrete manufacturing tasks to complex continuous flow operations.

Analog and Digital I/O Handling

PLCs excel in the processing of both analog and digital I/O signals, allowing for the accurate and adaptive control of various industrial parameters. Analog I/O handling enables the panel to interpret and utilize continuously varying signals, such as temperature, pressure, and flow, while digital I/O handling facilitates the management of binary signals from on/off switches and sensors. This dual capability empowers the PLC panel to monitor, regulate, and control an extensive range of industrial parameters and equipment with a high degree of precision.

Furthermore, the advanced I/O handling capabilities of PLCs extend to the implementation of signal conditioning, data filtering, and real-time parameter monitoring, thereby enhancing the reliability and responsiveness of industrial control systems. Whether it’s adjusting a motor speed based on a varying load condition or initiating a safety response based on a discrete sensor signal, the ability to seamlessly integrate and process analog and digital I/O signals is a hallmark of PLC functionality, driving the adaptive and precise control of industrial processes.

Data Storage and Retrieval

Another pivotal function of a PLC panel is the comprehensive management of data through robust storage and retrieval capabilities. PLCs can store, update, and retrieve a wealth of operational data, production parameters, and historical trends, serving as a central repository for essential information that underpins process optimization, diagnostics, and reporting. This data-driven functionality empowers industrial operators to monitor, analyze, and fine-tune their processes, thereby driving continuous improvement and informed decision-making.

Moreover, PLCs facilitate the real-time collection and archiving of performance metrics, alarm logs, and production statistics, enabling the generation of comprehensive reports and the identification of improvement opportunities. With their capacity to seamlessly store, organize, and access critical data, PLC panels play a pivotal role in harnessing the power of information to enhance process visibility, operational intelligence, and overall productivity within industrial settings.

Communication with Other Systems

PLCs are intrinsically designed to communicate and interface with a myriad of external systems and devices, forming the backbone of integrated industrial control and automation environments. Through standardized communication protocols, such as Ethernet, Modbus, and Profibus, PLC panels establish seamless connectivity with Human-Machine Interfaces (HMIs), Supervisory Control and Data Acquisition (SCADA) systems, remote I/O devices, and other PLCs, enabling centralized control, data exchange, and system coordination across diverse industrial domains.

This interconnected functionality fosters the creation of unified control and monitoring architectures, where disparate devices and systems converge to achieve holistic and synchronized industrial processes. By facilitating the exchange of real-time operational data, setpoints, and control commands, PLCs act as the central communication hub within automated environments, orchestrating the collaborative functioning of various system elements and enhancing overall operational coherence and responsiveness.

Alarm Management

Alarm management is a critical function of PLC panels, underpinning the proactive monitoring and response to abnormal process conditions and potential safety hazards. PLCs are equipped with sophisticated alarm management capabilities, enabling them to continuously monitor a multitude of process parameters and trigger predefined alarms and notifications in response to any aberrant readings or events. This proactive approach to alarm management ensures the swift detection and mitigation of potential issues, thereby bolstering the safety, reliability, and operational continuity of industrial processes.

Furthermore, PLCs offer comprehensive historical logging and analysis of alarm events, providing valuable insights into recurring issues, trends, and prevention strategies. By systematically capturing, categorizing, and analyzing alarm data, PLC panels play a pivotal role in implementing targeted maintenance and continuous improvement initiatives, thereby augmenting the overall resilience and performance of industrial systems.

Safety Features

Safety is a paramount consideration in industrial automation, and PLC panels are equipped with a diverse array of safety features and functions to mitigate risks and protect personnel and processes. PLCs can implement comprehensive safety interlock functions, emergency stop protocols, and fail-safe mechanisms to prevent the occurrence of dangerous conditions and swiftly halt processes in the event of safety breaches or emergencies. These safety measures are underpinned by rigorous diagnostic and testing protocols, ensuring the reliable performance of safety-related functions.

Moreover, PLC panels support the implementation of safety-related communication and coordination, allowing them to interact with other safety-critical devices and systems in a cohesive and harmonized manner. By integrating safety features and protocols into the overall control architecture, PLC panels contribute significantly to the establishment of robust safety cultures within industrial enterprises, safeguarding both personnel and equipment from potential hazards and ensuring compliance with stringent safety standards and best practices.

Diagnostics and Troubleshooting

PLCs are equipped with advanced diagnostic and troubleshooting features that play a pivotal role in identifying, isolating, and rectifying faults and anomalies within the control system. These features encompass iterative self-diagnostics, real-time error detection, and systematic logger analysis, enabling the PLC to generate detailed diagnostic data and pinpoint the location and nature of any issues that arise. This granular visibility into the system’s operational health and performance streamlines the troubleshooting process and minimizes unplanned downtime, crucial for maintaining the productivity and efficiency of industrial processes.

Furthermore, PLCs offer comprehensive backup and recovery functionalities, ensuring that the control programs, configuration data, and historical logs are systematically backed up and protected from potential loss or corruption. In the event of a system anomaly or failure, PLCs can swiftly restore the control environment to a pre-defined operational state, minimizing the impact of the incident and expediting the resumption of normal processes and operations. By embedding robust diagnostics, troubleshooting, and recovery capabilities into their operational framework, PLC panels fortify the overall reliability, maintainability, and resilience of industrial control systems.

This guide serves as a comprehensive resource for understanding the intricate components and multifaceted functions of PLC panels, offering invaluable insights into the critical role they play in fortifying the backbone of industrial automation and control. By delving into the key elements, such as the power supply, CPU, I/O modules, memory, and communication interfaces, as well as the invaluable functions encompassing I/O handling, data management, system communication, alarm management, safety measures, and diagnostic capabilities, readers gain a deep and holistic comprehension of the indispensable contributions of PLC panels to the efficiency, reliability, and safety of industrial operations.

Conclusion

In conclusion, understanding the key components and functions of a PLC panel is crucial for optimizing industrial automation and ensuring efficient and safe operations. Proper installation and maintenance practices are also essential for maintaining its reliability and performance. With this ultimate guide to PLC panels, you have all the information you need to know to effectively utilize this integral component in industrial control systems.